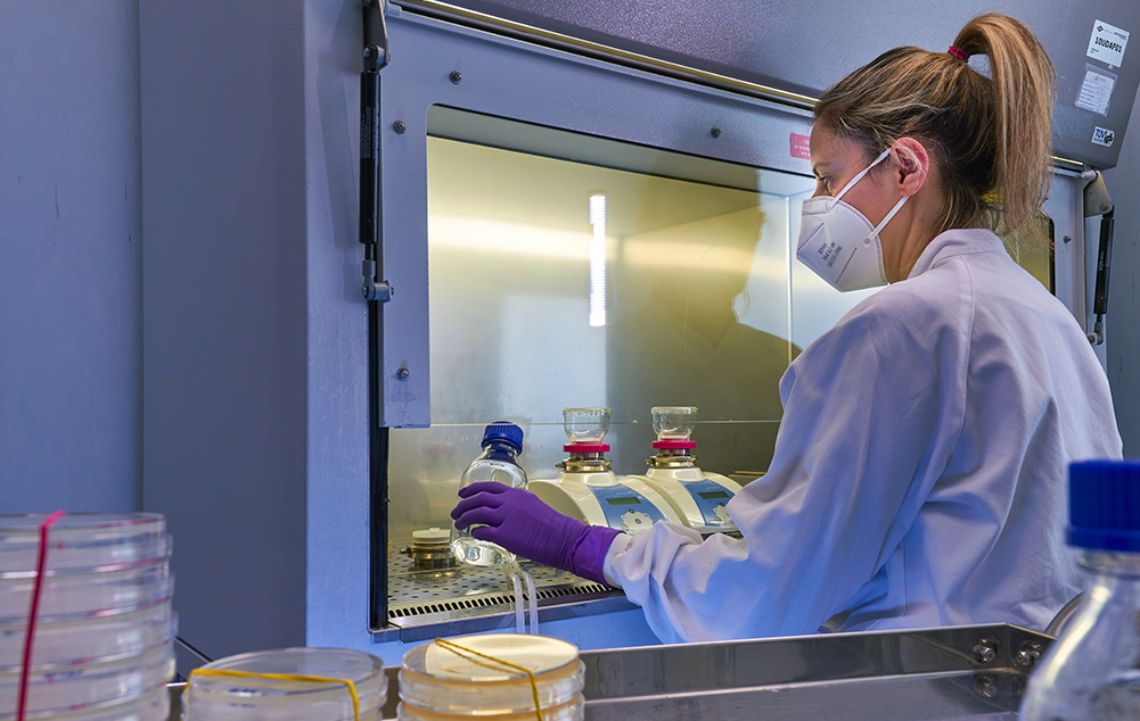

Innovation and technology are, in particular, the elements that distinguish the manufacturing sites in Lodi and Cassina de’ Pecchi: two plants that follow two different and specific production lines – each with peculiar characteristics and criticalities – that ensure very high quality and safety standards, thanks to the great attention paid to each individual process, thus representing one of the excellencies of the Made in Italy pharmaceutical production worldwide.

The secret of this excellence is the mix of some ingredients: on the one hand the industrial technological know-how, on the other the human capital, who guide and govern the processes. It’s the coordination and synergy created over time between the people working in the two plants that have made production activities increasingly effective and functional, despite the specificities characterising the works. Today we find out what are the peculiarities of the Lodi plant, whereas in the near future we will analyse the characteristics of the Cassina de’ Pecchi site.